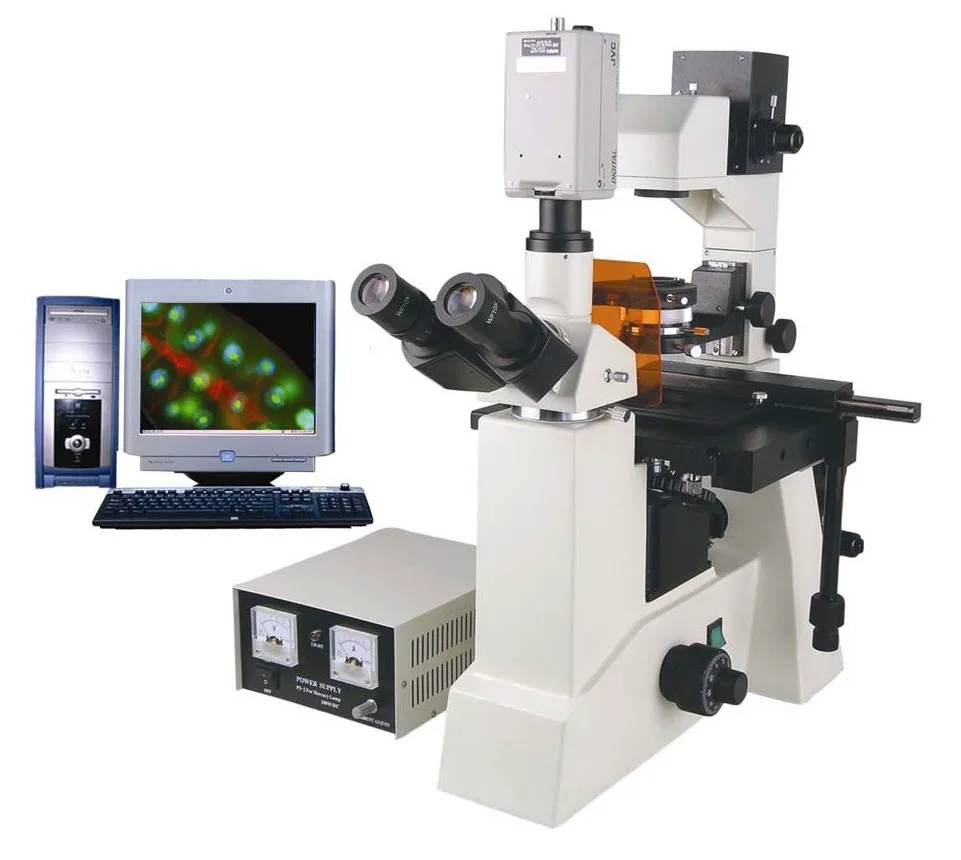

Industrial imaging is involved in many applications like engineering, detection, production, intelligence, transportation, robotics, security, and surveillance. Usually, optical filters are used to utilize enhancement and contrast.

Filters are the key components in the industrial imaging system. Normally it is used in front of a CCD or CMOS sensor to protect the lens from dust or block the unwanted wavelength of light.

Optical filters in industrial imaging applications could be divided into three categories:

The first is UV IR cut and IR cut. IR cut is a short pass filter that transmits a shorter wavelength and blocks a shorter wavelength. IR cut could transmit or block the light through when put in front of the sensor. This would help CMOS or CCD get the most appropriate light for imaging. Meanwhile, it ensures the image is not distorted whether day or night. The wavelength is different for different manufacturers. The common wavelength is IR cut 650nm, IR cut 750nm, IR cut 780nm, IR cut 680nm, IR cut 800nm, etc.

The second is UV IR cut or protective windows. UV IR cut is widely used in industrial imaging and photonics as their special property.

UV IR cut and protective windows are usually used in front of the lens. They are not so restricted on the surface quality or spectrum. So it is relatively easy for these filters to coat.

UV IR cut consists of a UV cut and an IR cut. Classic UV Cut filter is a long pass filter that blocks UV light and transmits the visible. Classic wavelength is UV310nm, UV 365nm, UV390nm, UV410nm, etc. IR cut classic wavelength is just as what is listed above ( IR cut 750nm, IR cut 650nm…) UV IR cut spectrum curve is a little like a bandpass. They block longer wavelengths than 700nm and shorter wavelengths than 410nm.

Protective windows is a glass coated with anti-reflection layers. OPTOLONG could offer protective windows as large as 150mm or as small as 3mm. The star one in the protective windows we produce is waterproof protective windows. Varies environmental test has been applied and improve its water resistance and durable in using.

The third is a bandpass filter. Bandpass filters always come with color. People would just say it is blue or red or yellow. They can be coated with abortive color glass or transparent glass. They could be as narrow as 10nm or as wide as 60nm. It depends on the application and request.

Other sorts of filters like Neutral Density filters or polarizing Filters won’t be listed as this is not our major business. However, if you have any requirement about them, contact us, please.