-

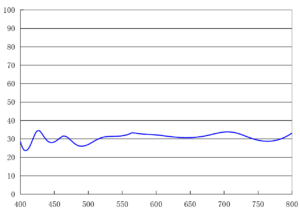

T30/R70 Beamsplitter

Filter Type : Beamsplitter

Wavelength: 400-800nm …

More Detail -

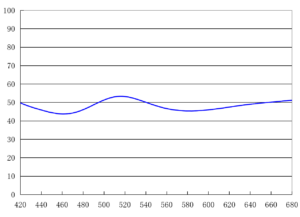

T50/R50 Beamsplitter

Filter Type : Beamsplitter

Wavelength: 420-680nm …

More Detail

Frequently asked questions

-

beam splitter: A beam splitter can split a beam of light into two or more beams. Each beam can propagate along a different path to achieve beam splitting.

Multi-channel measurement: In scientific research and experiments, a beam splitter can measure light of multiple wavelengths or spectral ranges simultaneously, thereby improving measurement efficiency. Image segmentation: In photography and video recording, a beam splitter can split light into multiple channels to capture different image information or capture light of different wavelengths.

Optical instruments: In optical instruments, a splitter beam is used to direct light to different detectors or channels to achieve different types of measurements and analysis.

Laser systems: Beam splitters can be used in laser systems to split laser beams into multiple channels for different applications such as medical treatment, material processing, and communications.

Medical imaging: In the field of medical imaging, splitter beams can split the incident beam into multiple channels to take different types of images or perform multimodal imaging.

Spectroscopic analysis: Beam splitters are widely used in spectral analysis to separate light of different wavelengths for precise spectral measurements. -

Optical beam splitter holograms are usually made of a variety of materials to meet different optical needs. Here are several common materials and their characteristics:

B270 advanced optical glass: This borosilicate glass is often used in beam splitters that require high transmittance due to its high transparency and good chemical stability.

Float glass: Manufactured through the float process, it has a very flat and uniform surface and is suitable for precision optical applications. Fused quartz and fused silica: These materials have excellent light transmittance in the UV to infrared range and are suitable for high-end applications.

Optical plastics: Such as polycarbonate and PMMA, which have the advantages of being lightweight and impact-resistant, are suitable for portable devices.

In addition, to optimize performance, beam splitters are often equipped with specialized optical coatings to enhance reflection or transmission. -

Yes, Optolong's T30/R70 beam splitters operate in the 400-800nm wavelength range, while the T50/R50 beam splitters operate in the 420-680nm wavelength range.

These specifications show that Optolong's beam splitters can meet a wide range of spectral needs, including parts of the UV and IR ranges. -

Regular cleaning: Dirt and grime can accumulate on the surface of the beam splitter, affecting its performance.

Use a suitable optical cleaner and lint-free cloth or optical paper for cleaning. Avoid using any rough materials that may scratch the surface or affect the coating.

Avoid scratches and physical damage: The optical surface of the beam splitter is very sensitive and any physical contact that may cause scratches or cracks should be avoided.

Proper storage: When not in use, the beam splitter should be stored in a dry, clean environment away from dust and moisture. It is best to store in a padded container to avoid direct contact with hard surfaces.

Avoid chemical damage: Certain chemicals may damage the beamsplitter coating. Avoid contact with harmful chemicals during cleaning and storage.

Check the coating: Regularly check whether the beamsplitter coating is peeling or damaged to avoid affecting the performance of the beamsplitter.

Control environmental conditions: When using and storing the beamsplitter, environmental conditions such as temperature and humidity should be controlled to prevent material aging or performance degradation. -

Yes, Optolong provides customized beamsplitter and polarization beamsplitter solutions for specific application needs. If you need customized services, you can contact Optolong by email at [email protected].

We have a professional team that can provide customized services based on your specific needs to ensure that the beamsplitter meets your application requirements. -

T30/R70 beam splitter: band range 400-800nm

T50/R50 beam splitter: band range 420-680nm

You can choose a specific wavelength as needed and contact Optolong for customization. -

A beam splitter is an optical device that splits a beam of light into two or more separate beams. It usually works by reflecting a portion of the light and transmitting the rest, using surfaces with specific coatings or materials such as glass or crystals. The exact ratio of reflected to transmitted light can be adjusted based on the design of the beam splitter.

The device relies on the principles of interference and reflection. When light strikes the beam splitter, a portion of the light is reflected from the surface, while the rest of the light passes through.

The coating or structure of the beam splitter determines the specific angles and ratios of reflection and transmission, enabling a variety of optical applications such as imaging, microscopy, and telecommunications. -

Yes, a beam splitter can change the polarization of light, depending on its design and the materials used. Conventional beamsplitters, especially those using metal or dielectric coatings, can preferentially reflect or transmit light depending on the polarization state of the incident light.

This means that they can change the polarization state by either enhancing a specific polarization in the reflected light or allowing another polarization to pass more freely.

For applications where a specific polarization state is required, a polarizing beam splitter is used. A polarizing beam splitter is used to split light into two beams with orthogonal polarizations - typically, one beam is s-polarized (perpendicular to the plane of incidence) and the other is p-polarized (parallel to the plane of incidence).

This makes polarizing beam splitters very useful in optical systems where the polarization state is controlled.