-

Protective Windows

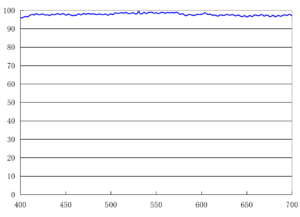

Filter Type : Anti-reflection

Wavelength: 420-680nm …

More Detail

Frequently asked questions

-

Regular cleaning is important to maintain optical clarity and performance. The cleaning process varies depending on the material and coating of the window. In general, it is recommended to use appropriate optical cleaning solutions and tools to avoid scratches and damage.

-

Optolong protective windows are designed to maximize transmission within a specific wavelength range while minimizing reflection and absorption. They protect optical systems and electronic sensors from the external environment.

-

Protective windows can be made from a variety of materials to suit different applications and environments. The AR coating used by Optolong mainly uses B270, float glass,K9 glass,fused silica, These materials are used because of their specific optical properties, including good light transmission and durability.

-

High borosilicate: low thermal expansion, impact resistance, and high temperature resistance. It is also resistant to chemicals and suitable for a wide range of wavelengths.

Fused Quartz: Known for ultra-low thermal expansion and excellent impact resistance. It is suitable for high temperature applications and provides excellent optical performance. -

Protective windows are used in a wide range of applications, including machine vision systems, industrial laser systems, medical devices, automotive, defense and aerospace applications.

-

Coatings such as anti-reflective (A/R) and oleophobic coatings increase light transmission, reduce reflection losses, enhance contrast and protect against smudges and scratches. This improves overall performance and longevity.

-

The choice depends on the specific requirements of your application, including desired wavelength range, environmental conditions and mechanical properties. It is important to consider the window's material transmission characteristics and optical surface specifications.