Dichroic mirrors, also known as color separation mirrors, are key components in optics. Dichroic mirrors are often used at angles of 45 degrees or 0 degrees. They can separate light beams according to light’s wavelength or polarization state.

This article will discuss the working principle, manufacturing process, application scenarios, advantages and difficulties, and future development trends of dichroic mirrors.

How Dichroic Mirrors Work

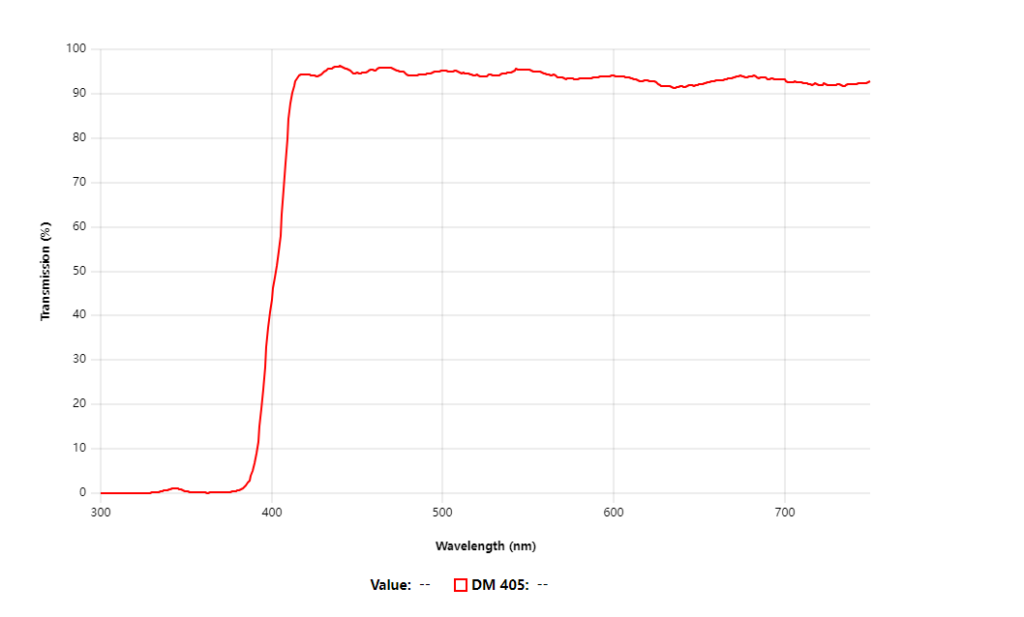

The working principle of dichroic mirrors is based on specific optical coatings and material selections that are precisely designed to allow only certain colors of light to pass through.

These lenses are usually composed of multiple layers of thin films with different refractive indices. As light passes through these layers, the various wavelengths of light are enhanced or weakened through interference effects.

By choosing the appropriate materials and adjusting the film thickness, the designer can ensure that only the target wavelength of light is allowed to pass, while other wavelengths of light are reflected or absorbed.

Manufacturing Process of Dichroic Mirror

The fabrication of dichroic mirrors is a complex and sophisticated process involving the deposition and optimization of multiple layers of dielectric films. The following are the key steps in making a dichroic mirror:

Material Selection

Commonly used dielectric materials include silicon dioxide (SiO2), titanium dioxide (TiO2), and alumina (Al2O3). These materials have different refractive indexes and can be matched appropriately to achieve the desired optical properties.

Thin Film Deposition Technology

- Electron beam evaporation: Using electron beams to heat materials, evaporate them, and deposit them on a substrate to form a thin film.

- Sputter deposition: bombards the target with ions, causing the material atoms to fly out and deposit on the substrate to form a thin film.

- Chemical vapor deposition (CVD): Gaseous compounds are decomposed at high temperatures and deposited on a substrate to form a thin film.

Click to learn: What is a dichroic mirror

Multi-Layer Design and Optimization

When designing a multi-layer structure of a dichroic mirror, computer simulation, and optimization software are needed to determine the thickness and material combination of each layer of film to achieve optimal optical performance.

Application of Dichroic Mirror

As a special optical material, dichroic mirrors are widely used in many fields. The following will introduce some typical usage scenarios to show how this material can effectively improve the performance of technology and products.

Microscope

In fluorescence microscopy, dichroic mirrors are used to separate excitation and emission light. The excitation light reaches the sample through the dichroic mirror, excites fluorescence, and then the emitted light enters the detection system through the dichroic mirror, thereby achieving high-contrast fluorescence imaging.

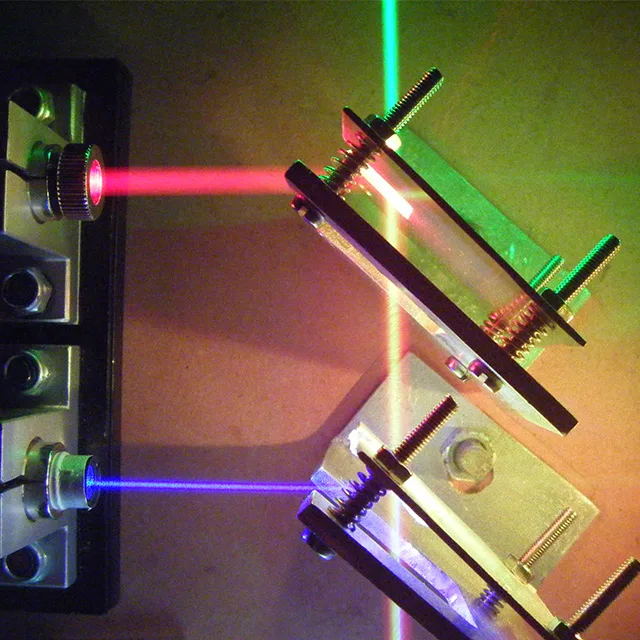

Laser Technology

Dichroic mirrors are used in lasers to combine and separate light beams. For example, dichroic mirrors can combine laser beams of multiple wavelengths into a single optical path, or separate beams of different wavelengths in a single optical path.

Imaging System

In hyperspectral imaging systems, dichroic mirrors are used to separate light of different wavelengths to obtain different spectral information, thereby improving image resolution and contrast.

Communication Technology

Dichroic mirrors are used in wavelength division multiplexing (WDM) technology in optical communication systems. They can separate or combine optical signals of different wavelengths to achieve high-speed data transmission and multiplexing.

Medical Equipment

In medical imaging equipment, dichroic mirrors are used to improve image quality. For example, in endoscopes, dichroic mirrors are used to separate visible and infrared light, allowing for clearer images.

Advantages and Difficulties of Dichroic Mirrors

Advantage

- High selectivity: Dichroic mirrors can accurately select and separate light of specific wavelengths, with extremely high reflectivity and transmittance.

- Low loss: Using dielectric materials, the optical loss of dichroic mirrors is very low, suitable for high-precision optical systems.

- Strong stability: The dielectric material has excellent thermal stability and chemical stability, allowing the dichroic mirror to maintain its optical performance in various harsh environments.

Difficulty

- Complex manufacturing: The manufacturing process of dichroic mirrors requires precise control of the thickness and uniformity of the film, which is complex and costly.

- Angle dependence: The performance of dichroic mirrors is sensitive to the angle of incident light, and this factor needs to be carefully considered in design and application.

- Environmental Dependence: Although dielectric materials are stable, in extreme environments the performance of dichroic mirrors may be affected, requiring additional protection.

The Development Prospects of Dichroic Mirrors

With the development of optical technology, the performance and application range of optical filters and dichroic mirrors are constantly expanding, and future development trends are gradually increasing, mainly including:

Application of New Materials

Researchers are exploring new dielectric and nanomaterials to further improve the optical performance and manufacturing efficiency of dichroic mirrors. These new materials can provide higher refractive index contrast and wider spectral selectivity.

Micro-Nano Structure Design

Using advanced micro-nano manufacturing technology, more complex micro-nano structures can be designed on the surface of dichroic mirrors. These structures enable fine control of light and improve the selectivity and efficiency of dichroic mirrors. For example, metamaterials can be used to achieve extraordinary control of light.

Multifunctional

Future dichroic mirrors may not only be used for light separation but may also integrate other functions. For example, dichroic mirrors are integrated with photodetectors to form optical devices with simultaneous detection and separation functions, thereby expanding their application range.

Reduce Costs

With the advancement of manufacturing technology and large-scale production, the manufacturing cost of dichroic mirrors is expected to be further reduced, making them widely used in more fields.

Environmental Adaptability

Research how to improve the performance and stability of dichroic mirrors in extreme environments, including applications in high temperature, high pressure, and strong radiation environments.

Conclusion

As an important optical element, the core principle of dichroic mirrors is based on the interference effect and filtering effect of light. Through the design and manufacturing of multi-layer dielectric films, it achieves selective reflection and transmission of light of specific wavelengths.

Despite difficulties such as manufacturing complexity and angle dependence, with the application of new materials and advances in micro-nano structure design, the performance and application prospects of dichroic mirrors will be broader, continuously providing important support for the innovation and improvement of optical systems.

Whether you want to buy or customize these filters, you can contact Optolong’s service team to get an accurate quote!

Related reading: Dichroic mirrors vs beamsplitters