An optical filter is a device that selectively transmits light of different wavelengths, usually implemented as a glass plane or plastic device in the optical path, which is either dyed in the bulk or has interference coatings. The optical properties of filters are completely described by their frequency response, which specifies how the magnitude and phase of each frequency component of an incoming signal are modified by the filter.

Filters mostly belong to one of two categories. The simplest, physically, is the absorptive filter; then there are optical interference filter or dichroic filters. Many optical filters are used for the optical imaging system and are manufactured to be transparent; some used for light sources can be translucent.

Optical filters selectively transmit light in a particular range of wavelengths, that is, colors while absorbing the remainder. They can usually pass long wavelengths only (long pass), short wavelengths only (short pass), or a band of wavelengths, blocking both longer and shorter wavelengths (bandpass).

The passband may be narrower or wider; the transition or cutoff between maximal and minimal transmission can be sharp or gradual. There are filters with more complex transmission characteristics, for example with two peaks rather than a single band; these are more usually older designs traditionally used for photography; filters with more regular characteristics are used for scientific and technical work.

Optical filters are commonly used in photography (where some special effect filters are occasionally used as well as absorptive filters), in many optical instruments, and in color stage lighting. In astronomy optical filters are used to restrict light passed to the spectral band of interest, e.g., to study infrared radiation without visible light which would affect film or sensors and overwhelm the desired infrared. Optical filters are also essential in fluorescence applications such as fluorescence microscopy filters and fluorescence spectroscopy filters.

Photographic filters are a particular case of optical filters, and much of the material here applies. Photographic filters do not need the accurately controlled optical properties and precisely defined transmission curves of filters designed for scientific work and sell in larger quantities at correspondingly lower prices than many laboratory filters. Some photographic effect filters, such as star effect filters, are not relevant to scientific work.

Ion Assisted Deposition (IAD) coating is based on a coating system as described before for Electron Beam Evaporation (EBE) but with an additional plasma source.

Physical Vapour Deposition (PVD) coating process is a thin-film technology which takes place in a vacuum and in which the layer is formed on the substrates through condensation of a material vapour.

The following are several types of optical coated filters

Optics coating filter guide:

Optical filter

Selectively transmits light of different wavelengths, interference filter reflects one or more spectral bands or lines and transmits others while maintaining a nearly zero coefficient of absorption for all wavelengths of interest.

Band pass filters

Bandpass filters are optical filters that only let a selected range of frequencies through. The bandwidth of a bandpass filter is the difference between the upper and lower frequencies of the passband.

The center frequency is the midpoint of the passband and is usually the design target for the filter.

These bandpass filters are mainly categorized into two types of filters wide band pass filter and narrow bandpass filter. A wideband bandpass filter has a wider bandwidth and hence its name which is the bandwidth over 30nm,and the narrow bandpass filter has an application to isolate a narrow region while rejecting all other wavelengths of light which a bandwidth of 10nm or less of the center wavelength.

Bandpass filters are used for many optical applications in LIDARS, LASER, medical, seismology, telecommunications, satellite communication systems, and data transfer for light modulation.

Dichroic filters

Also called “reflective” “thin film” or “interference” filters can be made by coating a glass substrate with a series of optical filters. Dichroic filters selectively pass light of a small range of colors and transmit the remainder. which uses the principle of interference.

Their layers form a sequential series of reflective cavities that resonate with the desired wavelengths. Other wavelengths destructively cancel or reflect as the peaks and troughs of the waves overlap. And also particularly suited for precise scientific work, since their exact color range can be controlled by the thickness and sequence of the coatings. They are usually much more expensive and delicate than absorption filters.

They can be used in devices such as the dichroic prism of a camera to separate a beam of light into different colored components.

Infrared cut-off filters

Designed to reflect or block mid-infrared wavelengths while passing visible light, sometimes called IR filters or heat-absorbing filters, are designed to reflect or block near-infrared wavelengths while passing visible light.

They are often used in devices with bright incandescent light bulbs (such as slide and overhead projectors) to prevent unwanted heating. There are also filters that are used in solid state (CCD or CMOS) video cameras to block IR due to the high sensitivity of many camera sensors to near-infrared light. These filters typically have a blue hue to them as they also sometimes block some of the light from the longer red wavelengths.

Long pass filters

Also called high pass filters, sometimes referred to as long pass edge filters, are designed to transmit wavelengths within a given wavelength range. This band is defined by the filter’s cut-on edge which essentially blocks frequencies shorter than the specified edge wavelength.

Short pass filters

Also called low pass filters a type of edge filter designed to pass wavelengths of light shorter than a given cut-off wavelength while blocking long wavelengths.

Reflective Mirror

A type of mirror composed of multiple thin layers of dielectric material on the glass substrate. Compared to the aluminum mirror, the dielectric mirror has better heat resistance and reflective performance. The average reflection rate in the visible light region is up to 98%, excellent visible light reflect at 45 degrees. In contrast, it also have anti reflective film coating technology, also known as anti-reflection coating filters

Beamsplitter

Also called beam splitter, is a piece of glass with a specialized mirror coating that perfectly reflects and high light transmittance at the same time. It is a crucial part of many optical experimental and measurement systems, such as interferometers, also finding widespread application in fiber optic telecommunications. The most demanded species in T30/R70 and T50/R50 at AOI 45 degrees.

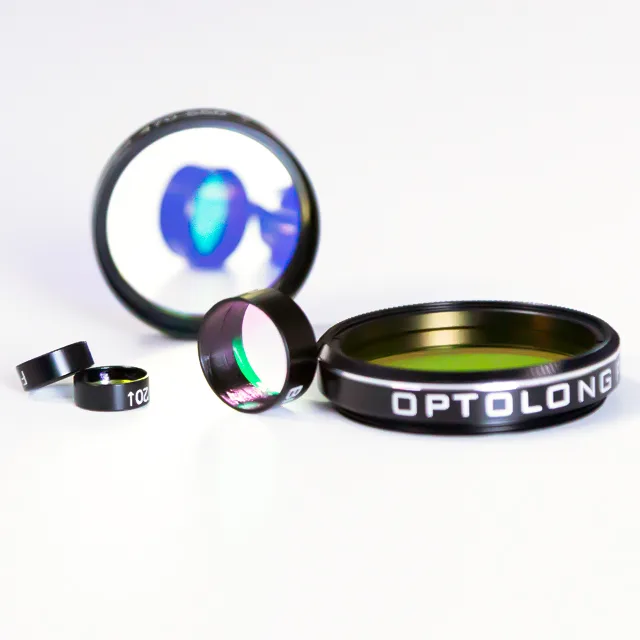

A photographic filter

A camera accessory consisting of an optical filter that can be inserted into the optical path. more astronomy filter looks on the Optolong astronomy web.

Hydrogen-alpha filter

An optical filter that transmits a narrow bandwidth of light centered on the H-alpha wavelength, more astronomy filter looks on the Optolong astronomy web.

Surface Flatness

In manufacturing and mechanical engineering, flatness is an important geometric condition for workpieces and tools. In the manufacture of precision parts and assemblies, especially where parts will be required to be connected across a surface area in an air-tight or liquid-tight manner, flatness is a critical quality of the manufactured surfaces.

| Figure | Cost | Applications |

| λ/2 | Low | Used where wavefront distortion is not as important as cost |

| λ/20 | High | For the most demanding laser systems where maintaining accurate wavefront is critical to performance |

| λ/10 | Moderate | For laser and imaging applications where low wavefront distortion, especially in systems with multiple elements |

| λ/5 | Moderate | Excellent for most general laser and imaging applications where low wavefront performance must be balanced with cost |

Surface Quality

The surface quality of an optical component is a specification that measures the surface imperfections of the component, these imperfections consist of scratches, dig (little pits), sleeks (tiny scratches), bubbles, edge chips, and coating blemishes.

| Scratch-Dig | Cost | Applications |

| 80-50 | acceptable | Acceptable quality can be easily fabricated |

| 60-40 | Moderate | Used for low-power laser and imaging applications with unfocused beams where scatter is not critical |

| 40-20 | High | Ideal for laser and imaging applications with collimated beams where scatter begins to affect system performance |