Optolong professionally manufacture optical thin film coating filters since 1999

Manufacturing Capabilities

Customize thin film coating

- Design coating: Based on clients’ requirements/applications;

- Processing waveband: Ultraviolet, Visible, Infrared, Near infrared ;

- Processing capability: Vacuum ion assisted coating (IAD), Hard coating;

- Coating types: Bandpass filters, Longpass filters, Shortpass filters, Anti-reflection filters, Beamsplitter, Dichroic mirrors;

- Main optical filters series:Astronomy filters , Fluorescence filters.

Coating technology

- Double-sided polishment substrate, good flatness and parallelism to avoid to halo/ghost image

- E-Beam gun

- Ion assisted coating, firm coating film, no wavelength shift

- Planet wheel coating fixture, wavelength consistency

Dust-free coating workshop & equipment

Optical coating is the key part of finished optical components. There are very strict requirements on environment when coating. Optolong owns class 10000 dust-free workshops. All optical filters are meticulously cleaned, coated and inspected in clean rooms.

- Coating equipment

- OPTORUN OTFC-1300

- Mars I 120

Quality Control

Optolong employs advanced spectrophotometers, measuring spectral range 190-3200nm. We perform spectral measurement of every production lot to ensure filters meet specification requirements.

- Spectrum measurement

- Shimadzu spectrophotometer

- PHOTON RT spectrophotometer

- Laser plane interferometer

- Collimator

- Goniometer

Get in touch

-

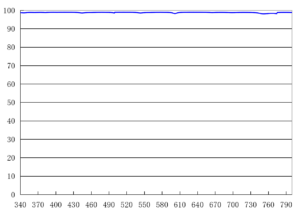

Reflective Mirror (340-800nm)

Filter Type : Reflective Mirror

Wavelength: 340-800nm …

More Detail -

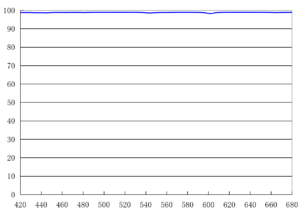

Reflective Mirror 420-680nm

Filter Type : Reflective Mirror

Wavelength: 420-680nm …

More Detail