Notch filters, also known as band-stop filters, are key components in optical systems. These filters selectively attenuate specific wavelength while allowing others to pass through unaffected.

Their high selectivity and ability to reject interfering signals make them often used in industries as diverse as telecommunications and medical imaging. In this blog, we’ll look in-depth at what notch filters are, their importance in optical systems, and more.

What are notch filters?

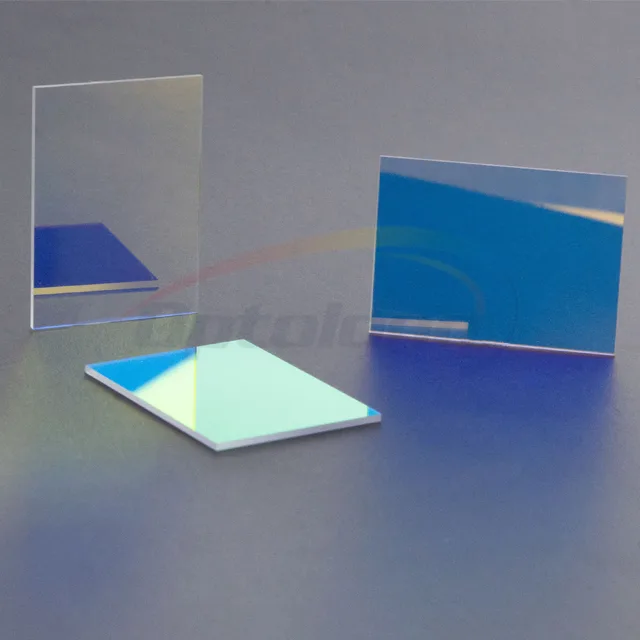

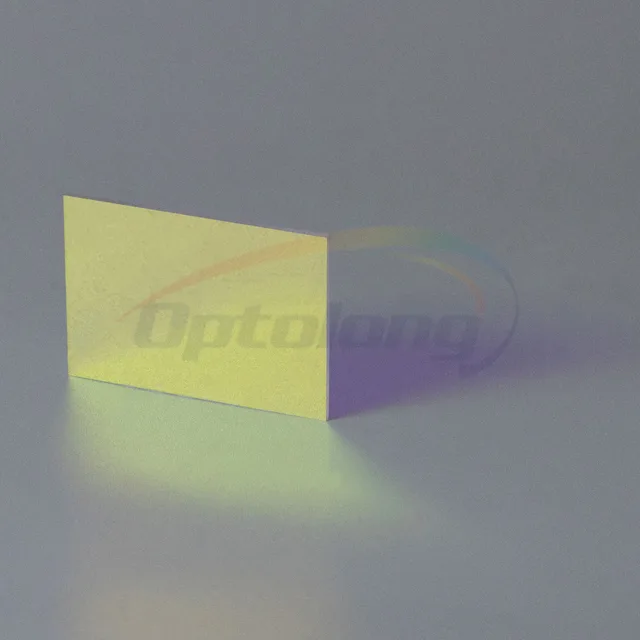

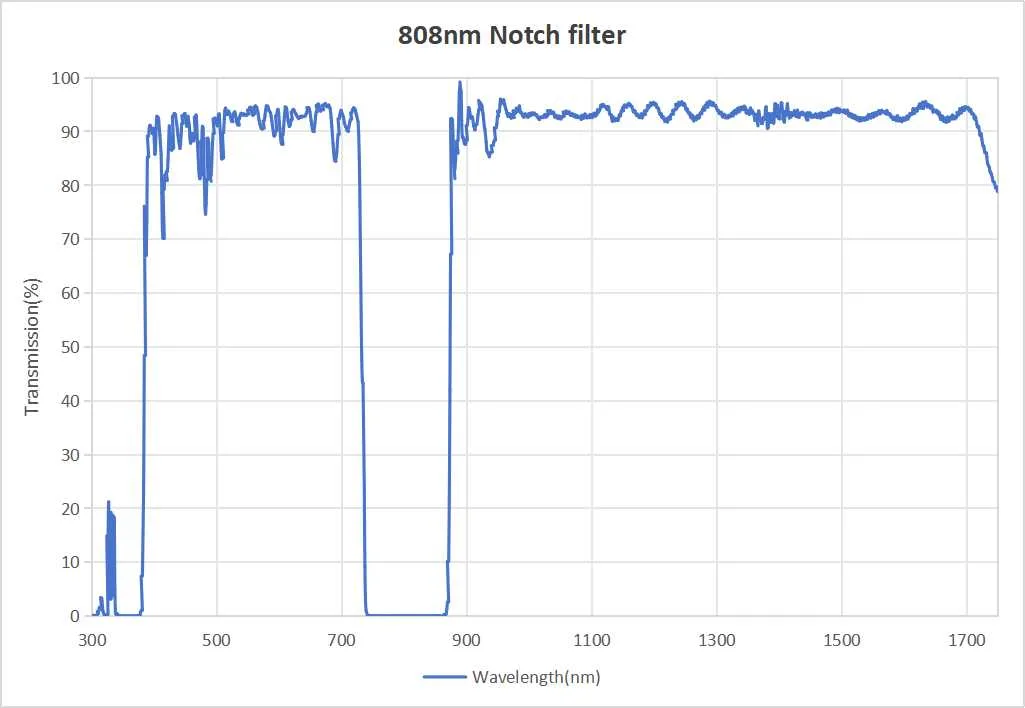

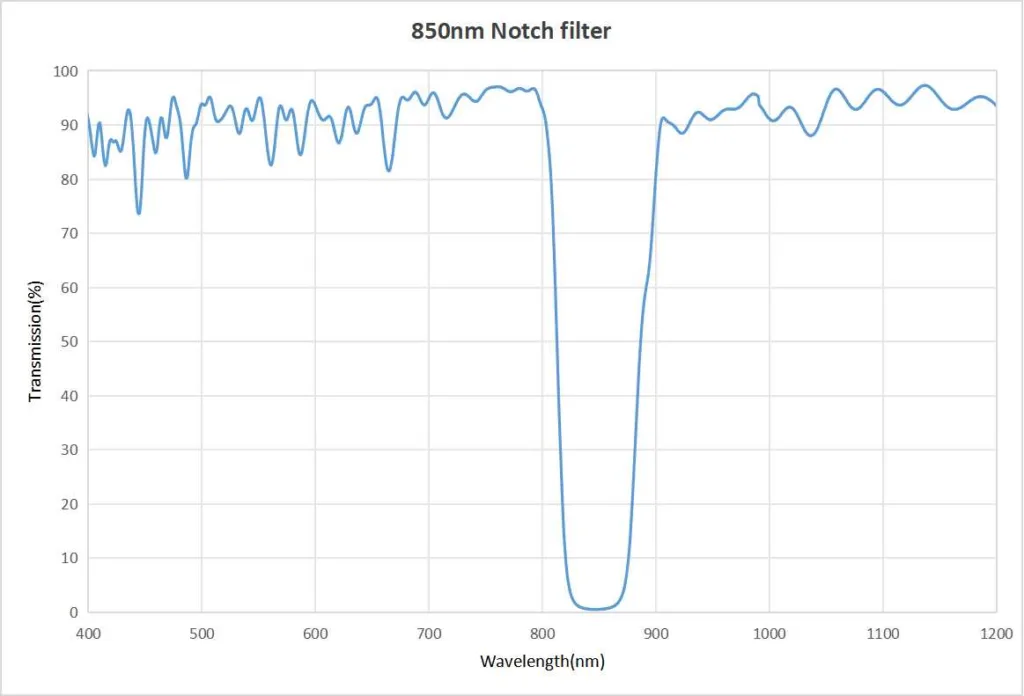

A notch filter is a special type of optical filter that achieve high transmittance over a wide wavelength range 90%,deep optics blocking OD>5.

These filters are often used to reduce or eliminate unwanted light, such as lasers or other specific wavelengths of light, without affecting the transmission of other wavelengths of light.

How a notch filter works

Notch filters work on the principle of phase cancellation interference, where the filtered wavelengths are phase-shifted, resulting in the wavelengths canceling each other. Through a clever combination of constructive and destructive interference, these filters effectively eliminate unwanted wavelength while maintaining the integrity of the desired signal.

Click to learn: Types of Bandpass Filters

Advantages and disadvantages

Benefits of using a notch filter

- Enables highly selective and precise wavelength control for improved signal quality.

- Ensure minimal interference by selectively attenuating specific wavelength within the optical system.

- Improves overall system performance by effectively blocking unwanted wavelengths.

- Maintains a high signal-to-noise ratio by minimizing signal loss during wavelength attenuation.

- Improves clarity and accuracy of transmitted signals by minimizing interference from external sources.

Potential disadvantages

- Balancing multiple performance parameters such as bandwidth and attenuation depth adds complexity to the design process.

- Ensuring precise spectral control and minimizing insertion loss requires meticulous attention to detail.

- The use of specialized materials and manufacturing techniques may result in higher manufacturing costs.

- Achieving optimal filtration performance may require investment in advanced technology and sophisticated equipment.

Types of notch filters

In the field of optical systems, there are two main types of notch filters: narrowband notch filters and wideband notch filters. Each type of notch filter has different uses depending on its design and operating characteristics.

Narrowband notch filters

Narrowband Notch Filters are used to suppress light in a narrow range of wavelengths while allowing other wavelengths to pass through. These filters are commonly used in laser systems to exclude specific wavelengths of laser light to minimize scattering or fluorescence interference.

Broadband notch filters

Broadband notch filters are designed to block or significantly attenuate various wavelengths of light while allowing other wavelengths to pass.

Broadband notch filters can cover a wider wavelength region than narrowband notch filters. They are very effective in applications where multiple wavelengths or a wider range of wavelengths need to be suppressed simultaneously.

This type of filter is often used in fields such as spectroscopy, imaging systems, and fiber optic communications, especially where broadband background or stray light needs to be removed from the signal. Broadband notch filters are effective in increasing the system’s sensitivity to specific wavelengths, thereby improving signal quality and contrast.

Design and manufacturing

Materials used

In the design of optical notch filters, dielectric materials, and metal materials are two key material choices. Dielectric materials such as silicon dioxide or tantalum pentoxide have specific dielectric properties that enable them to accurately attenuate specific wavelengths of light, directly affecting the spectral response and transmission efficiency of the filter.

In some applications, metal materials such as aluminum or gold are used to enhance reflective properties and effectively block unwanted wavelengths due to their unique optical properties.

By adding metal layers to the filter stack, customized spectral control can be achieved and signal isolation can be improved, thereby improving the overall performance of the filter.

Manufacturing technology

Thin film deposition and etching processes are two key technologies in the manufacturing process of notch filters. Thin film deposition techniques, including physical vapor deposition (PVD) and chemical vapor deposition (CVD), are used to form uniform and controlled optical coatings on the substrate surface, allowing precise control of coating thickness to optimize filter performance and tailor spectral characteristics to application requirements.

In addition, etching processes such as photolithography and reactive ion etching (RIE) are used to create complex patterns and geometries on thin film layers, ensuring precise wavelength selection and high-quality optical structures, thereby achieving sharp transitions between transmission bands and rejection bands.

Thin film deposition

Thin film deposition techniques are commonly used in the manufacture of notch filters to create uniform and controlled optical coatings. Methods such as physical vapor deposition (PVD) or chemical vapor deposition (CVD) can precisely control coating thickness to ensure optimal filter performance.

By depositing thin films on the substrate surface, manufacturers can tailor the spectral characteristics of notch filters to specific application requirements.

Etching process

Complex patterns and geometries are etched into thin film layers through techniques such as photolithography and reactive ion etching (RIE) to create precise wavelength-selective regions. This process allows the formation of high-quality optical structures with sharp transition edges between transmission and rejection bands.

Performance parameters

Notch filter design considerations include wavelength range and bandwidth, which together determine their performance and suitability for an application.

- Wavelength range, by optimizing the thickness and refractive index of the filter layers, can be tailored to block specific wavelengths of light, typically ranging from ultraviolet to infrared (approximately 200 nm to 2000 nm).

- Bandwidth defines the wavelength range of light waves that the filter blocks, and can be very narrow, just a few nanometers, or relatively broad, up to hundreds of nanometers, depending on the application requirements. Properly balancing these parameters allows for efficient, targeted optical filtering.

Conclusion

Our Notch filters are widely used in Raman spectroscopy ,Fluorescence Imaging/Microscopy.

These filters are specially designed to have OD6 cut off depth, high signal-to-noise ratio; The working range is extremely wide, 400-1500nm(similar competing products are generally 400-1200nm). The performance is stable and the wavelength is stable without deviation.

If you want to customize or purchase optical filters, including notch filters, bandpass filters, dichroic mirrors, or long and short pass filters, please visit Optolong’s official website to browse related products, or contact us for accurate quotes. We have a professional team to serve you!