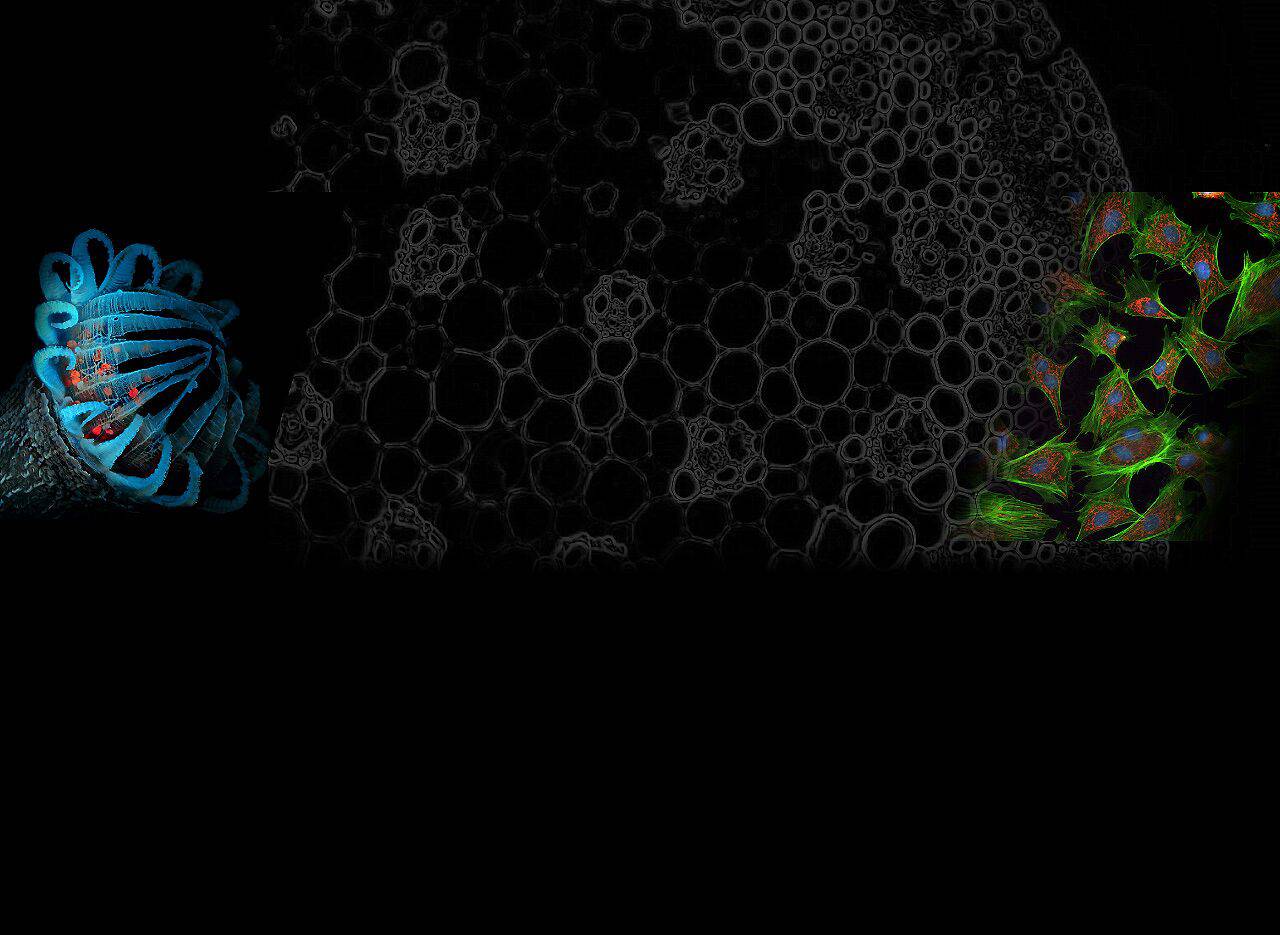

A bandpass filter is an optical component that allows light within a certain wavelength range to pass through while blocking light of other wavelengths. This filter is widely used in optical systems, such as biomedical imaging, fluorescence microscopy, laser systems, spectral analysis, etc.

This article will explore the production methods of bandpass filters in-depth, including their basic principles, design considerations, production process, and quality control.

Working Principle of Bandpass Filter

Bandpass filters mainly work based on the principle of interference and diffraction of light. Its structure is usually composed of multiple layers of thin film materials.

The thickness of these films and the refractive index of the materials determine which wavelengths of light will be reflected and which light will pass. The structural design of the film can achieve precise light wave selectivity by changing the thickness and number of layers of different materials.

Design principles of bandpass filters

1. Choosing the right material

The base material of the filter is usually glass or quartz, which has good transparency and mechanical strength. The thin film material needs to select the appropriate metal or dielectric material according to the specific wavelength of light. Common thin film materials include aluminum, silver, silicon dioxide, and magnesium fluoride.

2. Design and thickness calculation of thin film layer

The thin film layer’s thickness directly affects the filter’s optical performance. A filter with optimal transmittance in a specific wavelength range can be designed by calculating the interference effect of thin films of different thicknesses on light.

For bandpass filters, the thickness of the film is usually a multiple of one-quarter or one-eighth of the target wavelength, which allows light to interfere on the surface of the film, thereby achieving a bandpass effect.

3. Optical coating technology

Common coating technologies include chemical vapor deposition (CVD) and physical vapor deposition (PVD). CVD is mainly used to change the chemical substances in the thin film to form a new material film layer.

PVD is a physical coating of stable substances. Choosing the right coating technology can significantly improve the performance of the filter.

Steps for making bandpass filters

Before making the filter, you first need to select a suitable substrate material and perform surface treatment. The purpose of surface treatment is to remove any contaminants and particles that may affect the quality of the coating. Ultrasonic cleaning and chemical cleaning methods are usually used to treat the substrate surface.

1. Coating process

Vacuum coating technology is often used in the production of bandpass filters because it can accurately control the deposition rate and thickness of the film under high vacuum conditions.

By adjusting the coating time and the material evaporation rate, accurate film thickness can be obtained. To ensure the uniformity and stability of the film, a rotating substrate holder is usually used to ensure uniform coating at all angles.

2. Post-processing and quality control

After coating, the filter needs to undergo a series of post-processing, such as heat treatment or annealing, to eliminate stress in the film and improve its stability and durability.

Next, the performance of the filter is verified by methods such as transmission spectrum testing and anti-reflection testing. The results of the test will directly affect the final application effect of the filter.

Optimization and Customization of Bandpass Filters

The performance of the bandpass filter can be improved by optimizing the multilayer design, and increasing the bandwidth and stopband depth. For example, the multilayer structure can be designed with a combination of materials with different refractive indices. Reflection can be reduced and transmittance can be increased.

Filters require specific optical properties for different application scenarios (such as biomedical imaging, spectral analysis, laser systems, etc.). When customizing filters, it is necessary to consider the specific needs of customers, such as central wavelength, bandwidth, transmittance, and environmental durability.

Common Problems and Solutions

In the process of making and using bandpass filters, various problems may be encountered, such as scratches on the filter, film shedding, poor transmittance, etc.

These problems can be solved by improving the manufacturing process, strengthening quality control, and optimizing the design. In addition, correct use and maintenance methods can also effectively extend the service life of the filter.

Conclusion

Bandpass filters are indispensable components in optical systems. Their production involves multiple links such as material selection, thin film design, coating technology, and quality control. Through the introduction of this article, you can understand the basic production methods and precautions for bandpass filters, which provides a reference for the design and manufacture of high-performance filters in the future.

If you are choosing a specific bandpass filter, please visit the OPTOLONG website. They not only provide bandpass filters with a specific wavelength range but can also customize optical filters suitable for your application needs. Come and contact us for detailed information and accurate quotes!

Related reading: What is the use of bandpass filters?