ION beam assisted thin film coating (IAD)

Optolong applies ION beam-assisted evaporation (IAD) and e-beam thermal evaporation since 1999. ION-assisted technology enables us to design and manufacture the most sophisticated filters which need multi-layers deposition.

ION beam-assisted coating art and the coating machine OTFC-1300 from Optorun Japan enable filters to block the unwanted wavelength deep above OD7 on a single substrate. And also maintain the transmission as high as 96% at the same time. Spectrum properties of filters which coated out are very stable and durable to use and also keep consistent from lot to lot.

E-beam thermal evaporation coating art enables us to manufacture filters such as AR coating, protective windows which a large amount of application still needs.

OTFC-1300 Optical thin-film coater from Optorun

Model: OTFC-1300CBI/DBI

Optical Film Thickness Control System: HOM2-R-VIS350A High-precision Optical Monitor

Wavelength range:350nm to 1100nm Reflection/Transmittance

Crystal Film Thickness Monitor: XTC/3 plus 6-point rotary sensor

Evaporation Source EB source: 2 units

Mars I 120 optical thin film coater from Korea

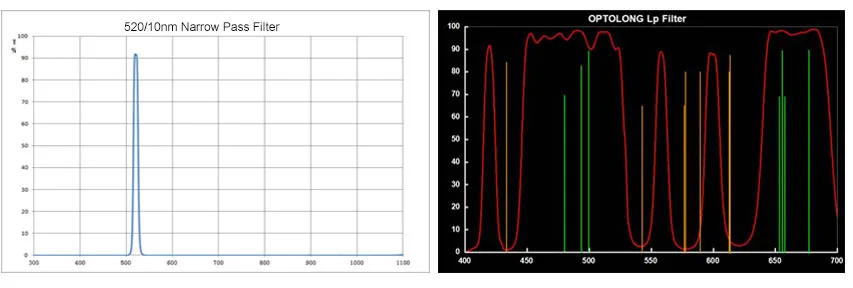

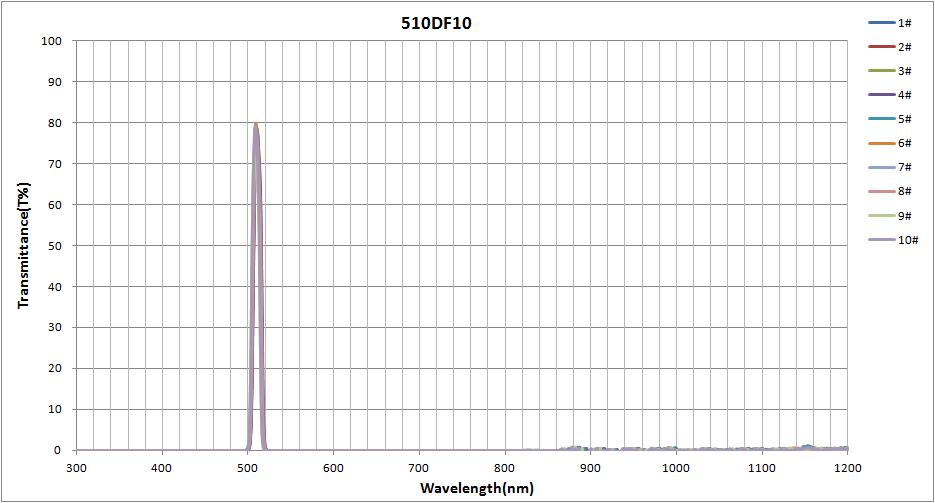

Filter spectrum performance:

Testing

•Laser plan interferometer: Flatness and parallelism test up to 1/20λ.

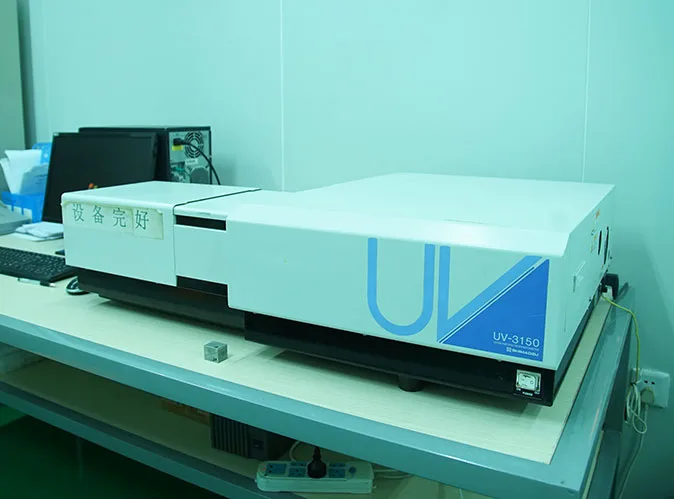

•Shimadzu spectrometer UV3150-Test spectrum wavelength 190-3200nm, Blocking depth above OD5.

•Spectrophotometer: Transmittance test+Blocking deep test.

•Parallel light pipe: Comprehensive products index assess.

•Goniometer: Angle error inspection.

Reliable–Precise–Repeatable

• Insensitive to temperature changes from -40°to 80°.

• The performance of filters lasting for years.

• Strictly to keep or meet the requirement of Meet MIL-C-48497A for physical and durability.

• Filters spectrum property controls within +/-1nm.

• Whether hundreds of filters in one round or many rounds, the filter’s property and performance keeps nearly the same.

Equipment capability

From Prototype to High Volume Optical filter production, Optolong has been in optical filter production for 18 years. We have the ability to design filters from the prototype and produce thousands of filters according to it. Thousands of filters whose spectrum is very complex can be produced to clients every day.

| Specification requirement | Single & Multiband pass filter | Longpass & Shortpass filter | Dichroic mirror & Beamsplitter |

| Transmission | <99.9% | <99.9% | <99.9% |

| Blocking depth | <OD10 | <OD10 | Reflection>99.5% |

| Standatd Specta Range | 200-1800nm | 200-1800nm | 200-1800nm |

| Standard Clear Aperture | 90% or client demand | 90% or client demand | 90% or client demand |

| Standard Scratch-Dig | 80/50 (60/40 or 40/20 or client demand) | 80/50 (60/40 or 40/20 or client demand) | 80/50 (60/40 or 40/20 or client demand) |

| Slope | <1%,(T90-T10) | <1%,(T90-T10) | <1%,(T90-T10) |

| Size(circle) | ∮150,∮4 | ∮150,∮4 | ∮150,∮4 |

| Size(square) | 150×150,3.5×3.5 | 150×150,3.5×3.5 | 150×150,3.5×3.5 |

| Temperature | -40℃~80℃ | -40℃~80℃ | -40℃~80℃ |

Sincerely,

Optolong Optics Ltd