When designing a machine vision system, it is important to enhance the contrast of the inspected object’s features of interest.Filtering provides a simple way to enhance the contrast of the image while blocking out unwanted illumination.

Many different types of filters in machine vision can be used to improve or change the image of the object under inspection. almost all can be divided into two primary categories: colored glass filters and coated interference filters,and the filter type is dependent on the application.

Each coated filter undergoes a unique manufacturing process to ensure proper performance. Wavelength-selective optical filters are manufactured by depositing dielectric layers on a specific substrate of alternating high and low refractive indices. The surface quality and uniformity of the substrate establishes the baseline optical quality of the filter, along with setting wavelength limits where the transmission of the substrate material falls off.

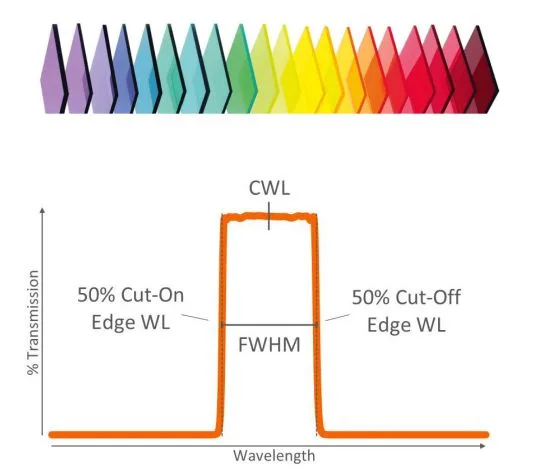

Coated filters typically offer sharper cut-on and cut-off transitions, higher transmissions, and better blocking than colored glass filters by creating constructive and destructive interference across a range of wavelengths. In addition to colored glass filters, there are a range of coated filters, that include hard coated fluorescent filters, dichroic filters, and polarizing filters. In most cases, interference filters can still provide better filtering control over a colored glass filter, but be aware of the potential pitfalls when using an interference filter with a wide-angle lens.

Many types of hard coated filters exist, such as bandpass, longpass, shortpass, and notch filters, each with a specified blocking range and transmission range. Longpass filters are designed to block short wavelengths and pass long wavelengths.

By using optical filters to improve the image contrast in machine vision. For more information, contact Optolong by calling 0086-871-68317717 or email us at [email protected].