A mirror image (in a plane mirror) is a reflected duplication of an object that appears almost identical but is reversed in the direction perpendicular to the mirror surface. As an optical effect, it results from reflection from substances such as a mirror or water. The application of reflection mirrors is a coating on the optical glass to increase the reflection of the substrate. Coated reflection mirror is superior to a normal reflection mirror as the reflection of a normal reflection mirror is lower and would make ghosting as there is no selection of wavelength.

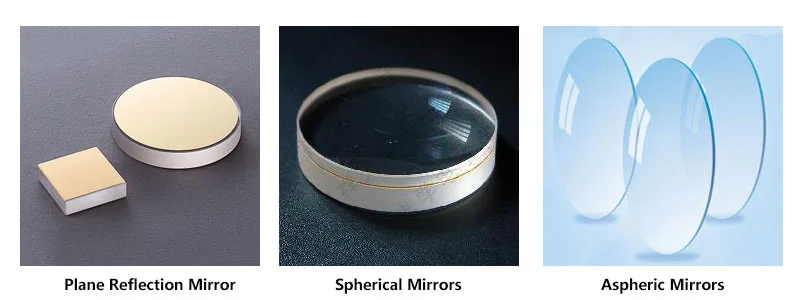

According to different shapes, reflection mirror can be divided into three species:

Plane reflection mirrors, spherical mirrors, and aspheric mirrors.

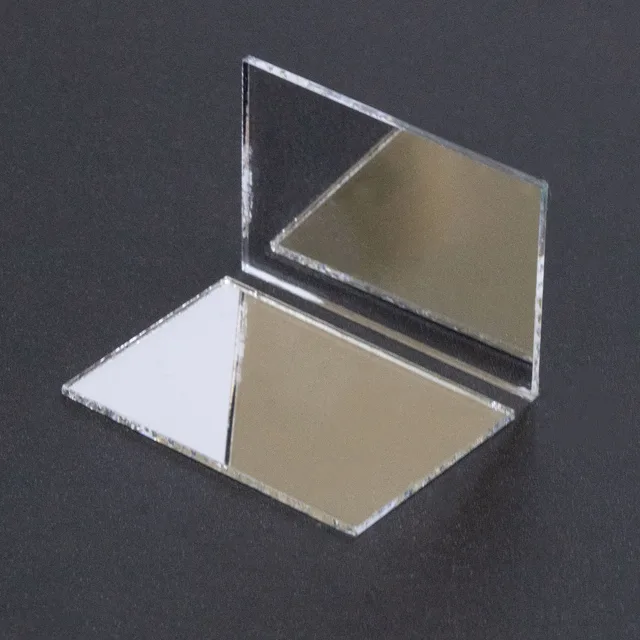

What we do is coat on the plat glass that is a plan reflective mirror. With the different degrees of reflection, it can be divided into full-reflection mirrors and half-mirrors. The half mirror is 50% reflection and 50% transmittance. It is also known as a beam splitter. When talking about reflection, there is also a reference to single point reflection and wide band reflection.

Below you could check some standard reflection mirrors we offer:

1. Full reflection mirror

AOI: 24°+/-1°

Spectrum: 420-680 nm @ Rave >99%,Rmin >98%

2. Half reflection mirror

AOI:45°

T/R=50%±8%

420-680 nm @ Rave >99 %,Rmin >98%

We accept OEM services for clients. For a quick response, the information below needs to be confirmed:

- AOI ( fixed angle of incidence or continually changing the angle of incidence)

2. The wavelength of single point reflection or wide band reflection

3. Size and other related info.

To learn more about reflection mirrors, please refer to our engineering team below.

Please contact our sales team to discuss a solution to your needs for reflective mirrors or coatings.